Ready to build your own Founder-Led Growth engine? Book a Strategy Call

Frontlines.io | Where B2B Founders Talk GTM.

Strategic Communications Advisory For Visionary Founders

Actionable

Takeaways

Extract payment early to validate corporate commitment:

Peter emphasized the critical importance of getting large corporations to pay for development work rather than providing it for free. "The only way you can ascertain whether what you're doing with them means something to the organization is to extract your pound of flesh for the privilege of working with you." Free pilots and proof-of-concepts don't validate whether a project has actual corporate backing and budget allocation.

Understand organizational incentive structures before scaling go-to-market:

Realtime Robotics learned this lesson the hard way when Toyota's manufacturing leadership rejected a solution that would save $50 million annually. The plant managers explained their incentives weren't aligned with cost savings but with production continuity: "If we adopt your technology wholesale and we save $50 million, I don't get any of that credit... But if you shut down my production line because you missed a detail or two, my ass is going to get fried." B2B founders must map decision-maker incentives, not just business value.

Time go-to-market investment carefully to avoid premature scaling: Peter identified a common startup trap:

"I think often... you start to gear up and bring resources on board that are going to consume your hard won investment dollars pretty quickly... if you haven't really done the work necessary, that's the quickest way to kill your company." The signal for scaling is clear: when people start buying consistently. For SaaS companies, the benchmark is reaching $1 million monthly recurring revenue before major go-to-market expansion.

Prepare for multiple category repositions as you discover market fit:

Realtime Robotics went through three different technology remakings and market positioning strategies over eight years. Peter noted they evolved from selling hardware products to major corporations to offering cloud-based SaaS solutions in the product lifecycle management category. Founders should expect their category definition to evolve as they learn from customer interactions and market resistance.

Raise capital during favorable cycles and conserve for downturns:

Having navigated multiple economic cycles, Peter stressed the importance of market timing: "Don't spend it just because you've got it, you know, sequester it away and use it when the rainy day comes. Because rainy days are going to come." The investment community cycles between enthusiasm and coldness, and successful founders learn to raise during good times while preparing for inevitable challenges.

Conversation

Highlights

The $70 Million Robotics Reality Check: How Realtime Robotics Learned Manufacturing’s Hardest GTM Lessons

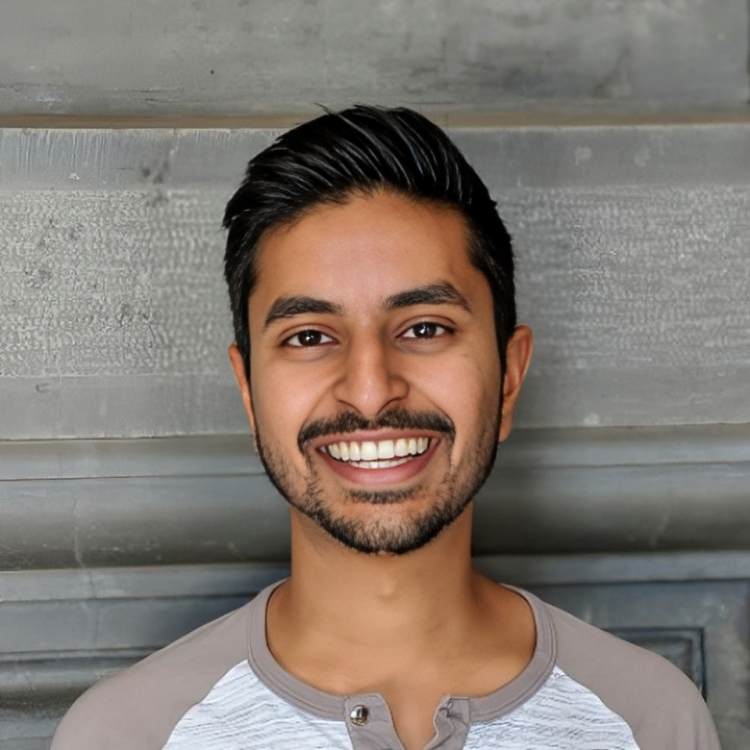

Most robotics companies promise to revolutionize manufacturing. Peter Howard, CEO & President of Realtime Robotics, spent eight years learning why that promise is harder to deliver than anyone expects.

In a recent episode of Category Visionaries, Peter shared the brutal reality of selling transformational technology to an industry that rewards caution over innovation. His journey from multiple IPO exits to building a $70 million manufacturing automation platform reveals the hidden forces that make or break enterprise deals.

The Perfect Storm That Wasn’t

Peter’s fifth startup began with what looked like entrepreneurial gold. Duke University had developed breakthrough robotics technology that caught attention at a major industry conference. Amazon, Toyota, and Samsung all expressed keen interest. For most founders, landing three Fortune 500 prospects before officially launching would signal inevitable success.

“We were very lucky that the breakthrough in technology had been kind of made public at a big robotics event and several major corporations, including Amazon, Toyota Motors and Samsung had expressed pretty keen interest,” Peter explains. “So this was kind of a birthday present that came with the group as we got started.”

But Peter’s decades of experience building companies taught him that corporate interest and corporate commitment are entirely different things. His approach was methodical: negotiate contracts that would fund development while securing eventual commercial terms.

This strategy stemmed from hard-won wisdom about enterprise sales. “The only way you can ascertain whether what you’re doing with them means something to the organization is to extract your pound of flesh for the privilege of working with you,” Peter notes. Too many startups give away development work for free, never validating whether their corporate partners have actual budget allocation and executive backing.

When Incentives Kill Billion-Dollar Opportunities

Three years into building Realtime Robotics, Peter felt confident enough to scale go-to-market operations. Toyota’s engineering teams had documented compelling value: their solution would save a typical facility $50 million annually by minimizing downtime and optimizing recovery cycles. With 36 facilities worldwide, the total opportunity exceeded $1.8 billion in annual savings.

The business case was bulletproof. The technology worked. The engineering teams were enthusiastic advocates. Everything pointed toward a massive enterprise win.

Then reality intervened in the form of production management incentives.

“The manufacturing, the head of manufacturing said, hold on a second, guys, you know, if we adopt your technology wholesale and we save $50 million, I don’t get any of that credit. That credit goes to the advanced engineering team. But if you shut down my production line because you missed a detail or two, my ass is going to get fried and I’m going to lose my job. So I’m not doing it, period,” Peter recalls.

This moment crystallizes a fundamental challenge in enterprise B2B: business value and decision-maker incentives often misalign completely. The plant managers who would implement the technology had nothing to gain from its success and everything to lose from its failure. No amount of ROI analysis could overcome that structural reality.

The Premature Scaling Trap

The Toyota rejection forced Peter to confront what he calls one of the most common startup traps: premature go-to-market scaling. “I think often, and I’ve been guilty of this myself, if you get feedback from the market that you know, if you’re an entrepreneur, you’ve got a good imagination, right? So you see the future state and you think you’re already very close. And so you start to gear up and bring resources on board that are going to consume your hard won investment dollars pretty quickly.”

Realtime Robotics had built up their team to about 65 people to meet anticipated demand. After the enterprise deals stalled, they had to downsize to 12 people to weather the storm. The experience reinforced Peter’s rule for sustainable scaling: “When people start buying it’s time to start selling.”

For SaaS companies specifically, Peter advocates waiting until you hit $1 million in monthly recurring revenue before major go-to-market expansion. “That’s really safe, right? If you’ve got that going, you can pretty safely invest a bunch more money in expanding that.”

Three Remakings and the Category Evolution

Rather than giving up after the manufacturing resistance, Peter led Realtime Robotics through what he describes as “three different remakings of our technology and how we bring it to the market.” Each iteration taught the team more about where their solution actually fit in the enterprise software ecosystem.

“We’ve actually probably gone through three different remakings of our technology and how we bring it to the market. So as we stand now, the products which we’re bringing to market are part of what we’ve learned is the product lifecycle management side of software and SaaS,” Peter explains.

This evolution from hardware products sold to individual corporations to cloud-based SaaS platforms integrated with CAD systems represents a fundamental shift in category positioning. Instead of selling robotics hardware, they became a software company serving the product lifecycle management market.

The transformation highlights an important principle for B2B founders: your initial category assumptions will likely be wrong. Market feedback and customer resistance patterns reveal where your solution actually creates value, which may be quite different from your original thesis.

Deterministic AI in a Probabilistic World

While the broader tech industry obsesses over large language models and generative AI, Peter maintains a pragmatic perspective on artificial intelligence in manufacturing contexts. “It’s a not like a large language model AI. It’s not probabilistic, it’s quite deterministic because you can’t have robots that crash into each other only 5% of the time. You need them to never crash into each other.”

This technical distinction reflects a deeper market reality. Manufacturing environments require reliability levels that current AI hype doesn’t address. Realtime Robotics’ AI generates robotic cycles automatically, but with the deterministic precision that production environments demand.

Peter’s skepticism extends to the humanoid robot trend that captures media attention. “A humanoid robot is like 6 to 10 of those put together so that you have 1 6th to 1 10th of that life cycle before they crash, before they fail. And Essentially what that means is that you need to have two or three humanoid robots to do one person’s job because the other two are going to be in the repair shop.”

Capital Discipline Across Economic Cycles

Having navigated multiple economic downturns across five startups, Peter emphasizes the importance of capital timing and discipline. “I think the investment community goes through wild cycles of being insanely enthusiastic by turns, insanely cold by other turns,” he observes.

His advice reflects hard-won experience: “What you can do is to raise money when the raising is good. Don’t spend it just because you’ve got it, you know, sequester it away and use it when the rainy day comes. Because rainy days are going to come.”

This philosophy proved prescient as Realtime Robotics faced challenges from the current political environment and tariff policies affecting their target markets. Companies that raised and conserved capital during favorable periods have more options when external forces create headwinds.

The Long View on Manufacturing Transformation

Today, Realtime Robotics operates with two main product lines: factory-based SaaS running on general purpose hardware and cloud-based SaaS connecting to CAD systems for automated robotic cycle generation. Their platform eliminates what Peter estimates is 90% of the complexity in robotic system deployment.

“The reason that were so interested in this is because if you can take the cost down by 50%, you open up a vast array of things which become suddenly economically viable. Picking strawberries, which, you know, compared to migrant labor, that’s a pretty challenging bar to get there. But it’s doable,” Peter explains.

The vision extends beyond individual applications to systemic transformation. With Toyota running 15-20% staffing deficits across all facilities globally, the labor shortage is forcing adoption of advanced robotics regardless of individual manager preferences.

Peter’s eight-year journey building Realtime Robotics illustrates the patience required to navigate complex enterprise markets. Success demands understanding not just technical requirements but organizational incentives, market timing, and the discipline to iterate through multiple category positions until finding sustainable fit.

For B2B founders tackling transformational technologies, Peter’s experience offers a sobering reality check: breakthrough innovation matters less than breakthrough understanding of how enterprises actually make decisions. The companies that survive long enough to figure that out often find opportunities worth the wait.